The Ultimate Guide to Laser Engraving on Wood: Using a Laser Engraver for Wood

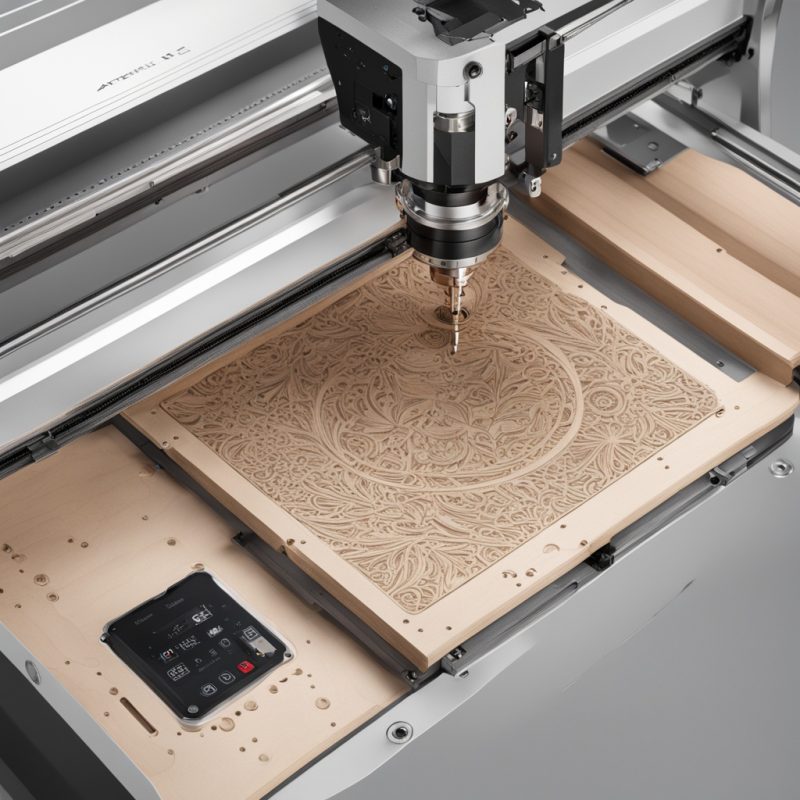

Laser engraving has revolutionized the way we create intricate designs on wood, offering precision and versatility that traditional methods simply cannot match. If you’re exploring **laser engraving** for woodworking projects, this guide will walk you through everything you need to know about using a laser engraver for wood. From understanding the basics of how it works to tips on achieving perfect results, this article is your comprehensive resource. Let’s dive in!

##

What Is a Laser Engraver for Wood?

A **laser engraver for wood** is a machine that uses a focused beam of light (laser) to intricate designs on wooden surfaces. Unlike traditional carving methods, which require manual effort and precision tools, laser engraving automates the process, ensuring accuracy and consistency every time. The machine works by directing a high-powered laser at the surface of the wood, burning away material layer by layer to create detailed patterns or text.

**Why choose a laser engraver for wood?** One of the biggest advantages is its ability to handle complex designs with ease. Whether you’re creating custom furniture, decorative items, or personalized gifts, a **laser engraver for wood** can bring your vision to life with precision and speed. Plus, it’s perfect for both small-scale projects and large-scale production.

##

Benefits of Using a Laser Engraver for Wood

Before diving into the technical aspects, let’s explore why a **laser engraver for wood** is a game-changer for woodworking enthusiasts:

- Precision and Accuracy: The laser beam is incredibly precise, allowing you to create intricate designs that would be nearly impossible with traditional tools.

- Speed: Laser engraving is much faster than manual carving, saving time and effort, especially for large-scale projects.

- Versatility: You can use the same machine to engrave on different types of wood, from softwoods like pine to hardwoods like oak or mahogany.

- Customization: With computer-controlled software, you can easily upload and edit designs, making it easy to create unique, personalized pieces.

- Longevity: Laser engravers are durable machines that require minimal maintenance, ensuring years of reliable use.

*Are you ready to take your woodworking projects to the next level?* A **laser engraver for wood** is a worthwhile investment if you want to enhance your creativity and efficiency.

##

How Does a Laser Engraver for Wood Work?

Understanding the basics of how a **laser engraver for wood** operates can help you make the most of its features. Here’s a overview:

1. **Laser Beam:** The machine generates a focused beam of light, typically using CO2 technology, which is ideal for engraving on wood.

2. **Software Control:** Design software is used to create or import your desired pattern. The software then translates the design into instructions for the laser engraver.

3. **Engraving Process:** The laser beam heats and vaporizes the wood surface layer by layer, creating a permanent mark without damaging the surrounding area.

*Can I use any type of wood with a laser engraver?* While most types of wood work well, some may require adjustments in settings to achieve optimal results. For example, hardwoods like maple or walnut are popular choices due to their smooth finish and ability to hold fine details.

##

Applications of Laser Engraving on Wood

Laser engraving is incredibly versatile, making it suitable for a wide range of woodworking projects. Here are some common applications:

- Custom Furniture: Add intricate designs or patterns to tables, chairs, and other furniture pieces.

- Decorative Items: Create wall art, picture frames, coasters, and other home decor items with personalized touches.

- Personalized Gifts: Engrave names, dates, or special messages on wooden jewelry boxes, cutting boards, or photo keepsakes.

- Artistic Projects: Use laser engraving to create detailed portraits, abstract designs, or geometric patterns for artistic expression.

- Industrial Applications: Laser engraving is also used in manufacturing to add serial numbers, logos, or product information on wooden packaging or components.

*What are the limitations of laser engraving?* While it’s incredibly versatile, laser engraving may not be suitable for all types of materials. For example, extremely thick or dense woods may require additional passes or adjustments to achieve desired results.

##

Choosing the Right Laser Engraver for Wood

If you’re considering purchasing a **laser engraver for wood**, it’s essential to choose one that meets your specific needs. Here are some factors to keep in mind:

- Budget: Laser engravers vary widely in price, depending on their features and capabilities. Determine your budget before making a purchase.

- Size and Power: Consider the size of your projects and the power requirements. Higher-powered machines are better for larger or thicker materials.

- Software Compatibility: Ensure the machine is compatible with design software you’re familiar with, or look for one that comes with user-friendly software.

- Add-On Features: Some laser engravers come with additional features like dust extraction systems or multi-axis capabilities, which can enhance functionality.

*Where can I find reviews of the best laser engravers for wood?* Online forums, woodworking communities, and product review sites are great resources to learn about user experiences and recommendations.

##

Maintenance Tips for Your Laser Engraver

To ensure your **laser engraver for wood** remains in optimal condition, follow these maintenance tips:

- Clean Regularly: Dust and debris can accumulate inside the machine, so clean it regularly using compressed air or a soft brush.

- Calibrate the Laser: Periodically check and adjust the laser focus to maintain precision in engraving.

- Store Properly: When not in use, cover the machine to protect it from dust and moisture.

- Replace Worn Parts: Over time, certain components like mirrors or lenses may wear out. Replace them as needed to ensure proper functioning.

*How often should I service my laser engraver?* It’s a good idea to schedule regular maintenance every few months, depending on usage frequency and intensity.

##

Frequently Asked Questions About Laser Engraving on Wood

Here are answers to some common questions about laser engraving on wood:

1. **Is laser engraving safe?**

Yes, but always follow safety guidelines, such as wearing protective eyewear and ensuring proper ventilation.

2. **Can I engrave dark-colored wood?**

Absolutely! Darker woods like walnut or mahogany can produce stunning results with laser engraving.

3. **How deep can a laser engrave into wood?**

The depth depends on the power of the machine and the type of wood, but most laser engravers can create marks up to a few millimeters deep.

4. **Can I remove an engraved mark from wood?**

Once engraved, the mark is permanent. However, you can sand it out if you make a mistake or want to start over.

5. **What’s the difference between laser engraving and laser cutting?**

Laser engraving creates markings on the surface, while laser cutting uses higher power settings to cut through materials completely.

*Is there anything I should avoid doing with my laser engraver?* Avoid engraving on wet wood or materials with high moisture content, as it can affect the quality of the engraving and potentially damage the machine.

##

Final Thoughts

Laser engraving has revolutionized woodworking by offering precision, creativity, and efficiency. Whether you’re a hobbyist, artist, or professional woodworker, investing in a **laser engraver for wood** can open up endless possibilities for your projects. With proper care and technique, you can create stunning, intricate designs that were once impossible with traditional methods.

*Are there any courses or tutorials available to learn laser engraving?* Yes, many online platforms offer courses on laser engraving techniques, software usage, and design tips. Take some time to explore these resources to enhance your skills!

So why wait? Dive into the world of laser engraving today and unlock your creative potential!