The Home Steel Laser Cutter: Your Ultimate Tool for Precision Engraving

Are you looking for a versatile and precise tool to bring your creative projects to life? Look no further than the **home steel laser cutter**. This cutting-edge device is revolutionizing the way people approach engraving, cutting, and crafting. Whether you’re a hobbyist, DIY enthusiast, or professional artist, this machine offers endless possibilities. In this article, we’ll explore everything you need to know about the **home steel laser cutter**, its benefits, how it works, and how you can use it for your projects. Let’s dive in!

What is a Home Steel Laser Cutter?

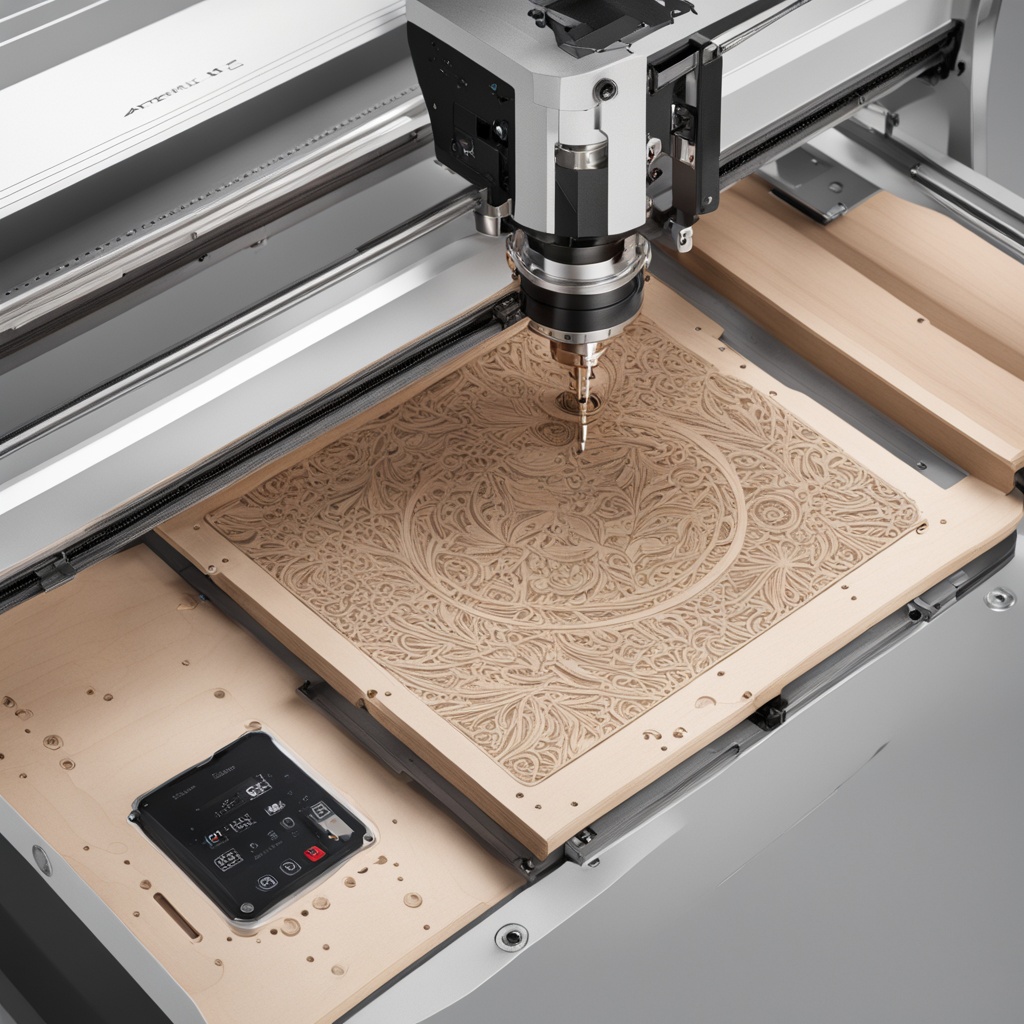

A **home steel laser cutter** is a compact yet powerful machine designed for precision cutting and engraving on various materials, including wood, metal, plastic, and more. Unlike traditional tools, it uses a focused laser beam to create intricate designs with remarkable accuracy. This makes it an ideal choice for both small-scale projects and large-scale productions.

If you’re wondering, *”What can I do with a home steel laser cutter?”* the answer is simple: almost anything! From crafting personalized gifts to creating professional-grade signage, this machine opens up a world of creative opportunities. Let’s explore some of its key features and benefits.

Benefits of Using a Home Steel Laser Cutter

The **home steel laser cutter** offers numerous advantages that make it a must-have tool for any workshop or home studio. Here are just a few reasons why you should consider investing in one:

- Precision and Accuracy: The laser beam ensures clean, precise cuts and engravings, even on complex designs.

- Versatility: It can work with a wide range of materials, making it suitable for various projects.

- User-Friendly: Most models come with intuitive software that allows even beginners to create professional-quality results.

- Time-Saving: The machine operates at high speeds, reducing the time needed to complete projects.

- Cost-Effective: With minimal material waste and long-lasting components, it’s an investment that pays off over time.

*”How does a laser cutter work?”* you might ask. Let’s break it down in the next section.

How Does a Home Steel Laser Cutter Work?

The **home steel laser cutter** operates by directing a high-powered laser beam at the material being cut or engraved. The laser heats the material to extremely high temperatures, either vaporizing or melting it away. This process is controlled by software that guides the laser according to the design uploaded by the user.

Here’s a step-by-step overview of how it works:

- Design Your Project: Use computer-aided design (CAD) software or vector graphics to create your design.

- Upload the Design: Transfer the design to the laser cutter’s control software.

- Select Material and Settings: Choose the material you’re working with and adjust the settings for optimal performance.

- Start the Process: The machine will begin cutting or engraving according to your design.

- Add Finishing Touches: Once complete, you can sand, paint, or assemble your project as needed.

*”What materials can I use with a home steel laser cutter?”* Let’s explore that in the next section.

Materials You Can Use With a Home Steel Laser Cutter

The **home steel laser cutter** is compatible with a wide variety of materials, making it incredibly versatile. Some of the most popular options include:

- Wood: Perfect for creating custom furniture, decorative items, and signage.

- Metal: Ideal for producing precision parts, jewelry, and metal art.

- Plastic: Great for crafting signs, models, and prototypes.

- Fabric: Can be used to create intricate designs on textiles.

- Glass: Enables the creation of decorative patterns and cuts on glass surfaces.

*”How do I ensure the best results when using my home steel laser cutter?”* Proper preparation and following safety guidelines are essential. Let’s discuss that next.

Tips for Getting Started With Your Home Steel Laser Cutter

If you’re new to laser cutting, here are some tips to help you get the most out of your machine:

- Familiarize Yourself with the Software: Spend time learning how to use the design and control software provided with your cutter.

- Start Small: Begin with simple projects to gain confidence before tackling more complex designs.

- Experiment with Materials: Test different materials to understand their behavior under the laser beam.

- Maintain Your Machine: Regularly clean and maintain your cutter to ensure optimal performance over time.

*”Where can I buy a reliable home steel laser cutter?”* You can find high-quality models online, including the one available at .

Creative Projects to Try With Your Home Steel Laser Cutter

The possibilities with a **home steel laser cutter** are endless. Here are some project ideas to inspire you:

- Custom Keychains: Create personalized keychains with names, dates, or symbols.

- Furniture Accessories: Design and cut custom handles, pulls, or decorative elements for furniture.

- Artwork: Produce intricate wall art, coasters, or decorative plates.

- Jewelry: Make unique pieces like pendants, earrings, or rings.

- Signage: Create professional-grade signs for your home or business.

*”How can I share my laser cutting projects with others?”* Consider joining online communities or social media groups dedicated to DIY and crafting. You’ll find inspiration, tips, and support from fellow enthusiasts.

Safety Precautions When Using a Home Steel Laser Cutter

While the **home steel laser cutter** is a powerful tool, it’s important to prioritize safety. Here are some essential precautions:

- Protect Your Eyes: Always wear protective eyewear when operating the machine.

- Ventilate Properly: Ensure your workspace is well-ventilated to avoid inhaling fumes from the cutting process.

- Follow Instructions: Read and follow the manufacturer’s guidelines carefully.

- Keep It Clean: Regularly clean the machine to prevent dust buildup, which can interfere with its performance.

*”What are common mistakes to avoid when using a laser cutter?”* Overloading the machine, improper material alignment, and neglecting safety measures are some of the most frequent errors. Take your time and double-check your setup before starting any project.

Maintenance Tips for Your Home Steel Laser Cutter

To keep your **home steel laser cutter** running smoothly, follow these maintenance tips:

- Clean the Lens Regularly: Dust and debris on the lens can reduce cutting efficiency. Use a soft cloth or specialized cleaning solution to maintain clarity.

- Check Belts and Pulleys: Inspect these components for wear and tear, replacing them as needed.

- Calibrate Regularly: Ensure the machine is properly calibrated to maintain accuracy in cuts and engravings.

- Store Properly: When not in use, store your cutter in a dry, dust-free environment.

*”How often should I perform maintenance on my laser cutter?”* It depends on usage frequency, but a monthly checkup is generally recommended to prevent issues and extend the life of your machine.

Frequently Asked Questions About Home Steel Laser Cutters

- Q: Can I cut metal with my home steel laser cutter?

A: Yes, many models are capable of cutting various metals, including steel. However, the thickness and type of metal will affect performance. - Q: What is the difference between a laser cutter and a CNC machine?

A: Laser cutters use focused light beams to cut materials, while CNC machines use mechanical tools for more precise shaping and engraving. - Q: Is it difficult to learn how to use a laser cutter?

A: With practice and guidance, most users can become proficient in operating a laser cutter. Online tutorials and user manuals are excellent resources for learning.

*”Where can I find more information about laser cutting techniques?”* Look for online courses, instructional videos, or local workshops that offer hands-on experience with laser cutters.

Conclusion

A **home steel laser cutter** is a versatile and powerful tool that can transform your crafting and DIY projects. With the right skills and precautions, you can create stunning, precision-cut pieces in a variety of materials. Whether you’re a hobbyist or a professional, investing in a high-quality laser cutter can open up new creative possibilities for your work.

*”Are there any alternative tools I could use if I don’t have access to a laser cutter?”* Consider using CNC machines or manual cutting tools as alternatives, though they may not offer the same level of precision and speed as a laser cutter.

Happy crafting!