“

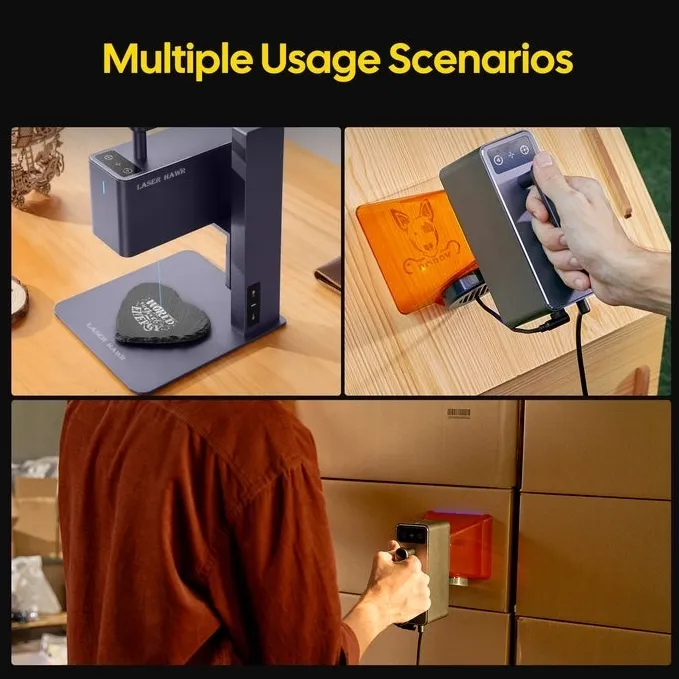

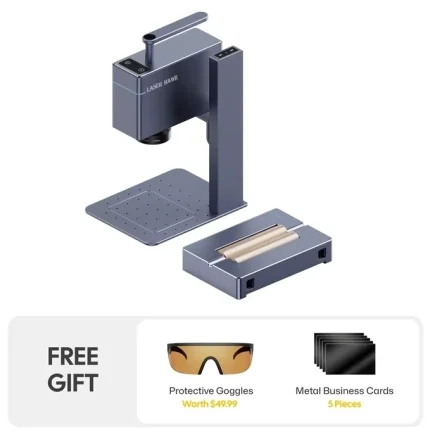

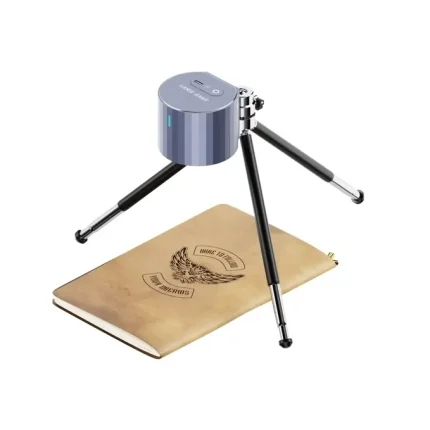

Introducing the LaserHawk LH2, a state-of-the-art laser engraving and cutting machine designed to revolutionize your creative and industrial projects. Whether you’re a hobbyist, a small business owner, or a professional manufacturer, the LaserHawk LH2 offers unparalleled precision, versatility, and performance.

With its advanced infrared laser engraver uses, the LaserHawk LH2 is capable of engraving and cutting a wide range of materials, including wood, acrylic, leather, and even laser engraver metal. This makes it an ideal choice for a variety of applications, from custom signage and jewelry making to industrial part marking and prototyping.

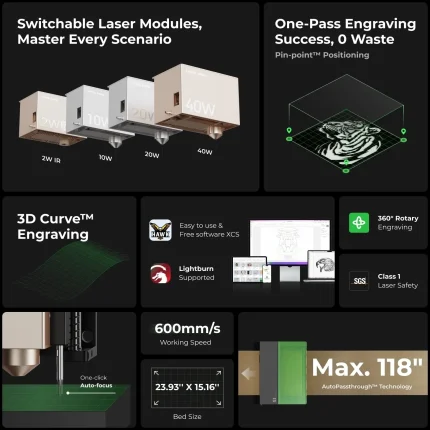

- High Precision: The LaserHawk LH2 boasts a cutting-edge laser system that delivers micron-level accuracy, ensuring every detail of your design is captured perfectly.

- Versatility: From intricate engravings to precise cuts, this machine handles it all with ease. Its compatibility with various materials makes it a versatile tool for any project.

- User-Friendly Interface: Equipped with an intuitive control panel and software, the LaserHawk LH2 is easy to operate, even for beginners. Spend less time learning and more time creating.

- Durability: Built with high-quality components, the LaserHawk LH2 is designed to withstand heavy use, ensuring long-lasting performance and reliability.

- Safety Features: Safety is a top priority with the LaserHawk LH2. It includes advanced safety mechanisms such as emergency stop buttons, protective enclosures, and ventilation systems to ensure safe operation.

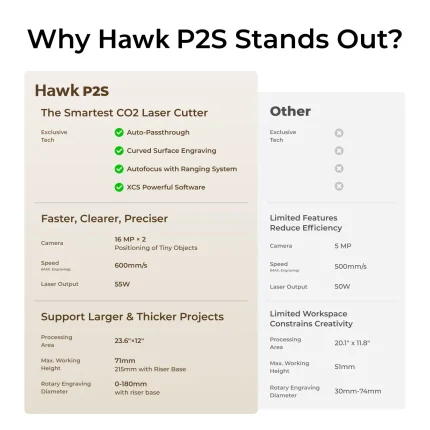

When compared to other machines like the epilog laser engraver, the LaserHawk LH2 stands out with its superior speed, precision, and affordability. It’s the perfect blend of professional-grade performance and user-friendly design, making it a must-have tool for anyone serious about laser engraving and cutting.

Transform your ideas into reality with the LaserHawk LH2. Whether you’re engraving intricate designs on metal or cutting precise patterns in wood, this machine delivers exceptional results every time. Experience the future of laser technology today!

More you like:

Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series

Eduardo Wilson (verified owner) –

**Laser Engraver Experience: Custom Leather Coasters**

1. **Specific Project Experience:**

– **Project:** Custom leather coasters with intricate designs.

– **Material Behavior:** Leather requires precise power control to avoid smoking and discoloration during engraving.

– **Challenges & Solutions:** Encountered issues with smoking, resolved by implementing a ventilation system and adjusting laser settings for optimal results. Achieved clean engravings without burns.

2. **Technical Performance:**

– **Power Control:** Adjusted power settings to prevent burning while ensuring deep enough engraving for durability.

– **Precision:** Maintained fine details on small coasters, showcasing intricate patterns effectively.

– **Software & Features:** Utilized vector design software with plugins for leather engraving, enhancing consistency. Leveraged air assist feature to reduce smoking and improve cut quality.

3. **Business/Creative Impact:**

– **New Product Line:** Introduced custom leather coasters, attracting a niche market interested in personalized items.

– **Customer Feedback:** Positive reception on the product’s durability and aesthetic appeal.

– **Workflow Improvement:** Efficient batch production capabilities streamlined operations, allowing for quick turnaround times.

4. **Comparison & Value:**

– **Previous Methods:** Replaced manual engraving, which was time-consuming and less precise.

– **Cost-Effectiveness:** Reduced material wastage and minimized touch-ups, lowering overall costs.

– **Time Savings:** Faster processing times and efficient production contributed to significant time savings.

Overall, the laser engraver has been a valuable asset, enabling the creation of high-quality, customized leather products that have enhanced my business offerings and customer satisfaction.

Jessica Davis –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”