“

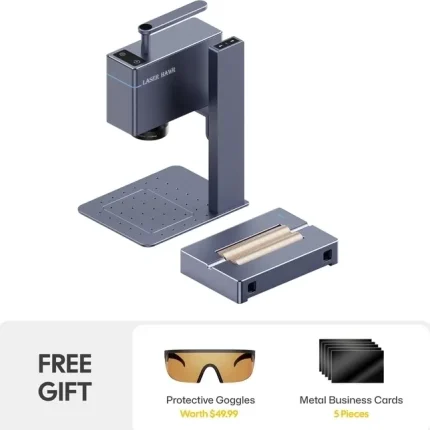

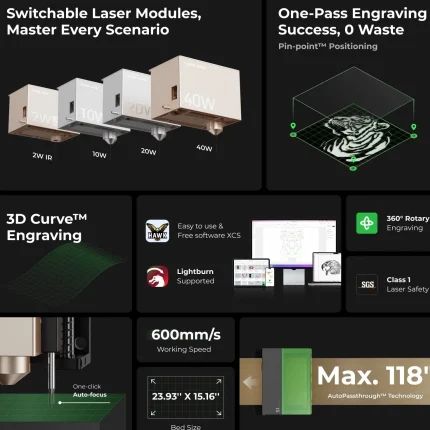

Introducing the LaserHawk LH4, a state-of-the-art laser engraver machine designed to revolutionize your creative and industrial projects. Whether you’re a hobbyist, small business owner, or industrial professional, the LaserHawk LH4 combines precision, power, and versatility to meet all your engraving and cutting needs.

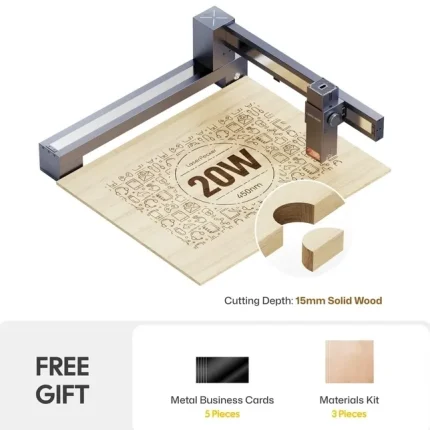

This laser cutter and engraver is engineered to handle a wide range of materials, including wood, acrylic, leather, and even metal. With its advanced laser technology, the LaserHawk LH4 delivers unparalleled accuracy, making it perfect for intricate designs, detailed engravings, and precise cuts. Wondering how much to charge for laser engraving a cutting board? With the LaserHawk LH4, you can maximize your profitability by offering high-quality, custom engravings at competitive rates.

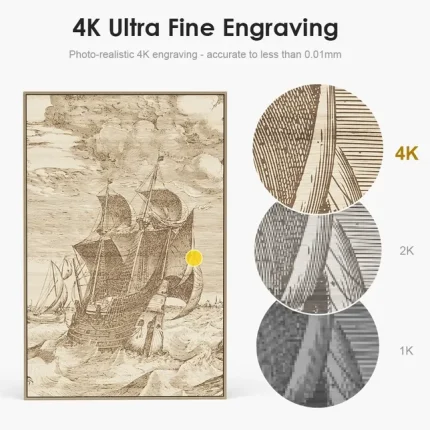

- High-Precision Laser Technology: Achieve flawless engravings and cuts with pinpoint accuracy, even on complex designs.

- Versatile Material Compatibility: From wood and acrylic to metal, the LaserHawk LH4 handles it all with ease.

- User-Friendly Interface: Designed for both beginners and experts, the intuitive controls make operation seamless.

- Durable Construction: Built to last, the LaserHawk LH4 ensures long-term reliability and performance.

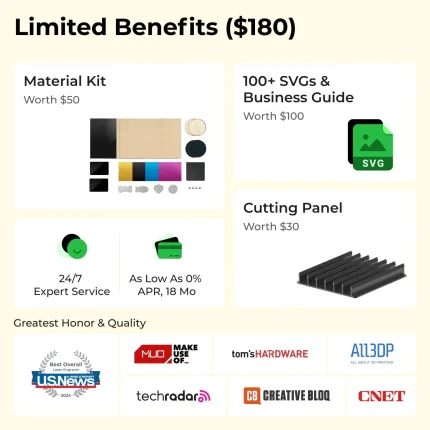

- Cost-Effective: Optimize your pricing strategy with efficient operation and low maintenance costs.

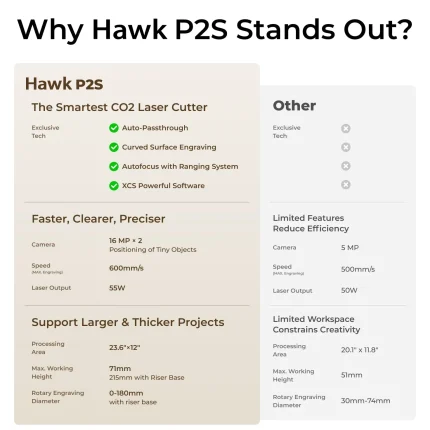

Compared to other models like the xtool laser engraver, the LaserHawk LH4 stands out with its superior build quality, enhanced features, and competitive pricing. Whether you’re engraving a cutting board, creating custom signage, or cutting intricate patterns, the LaserHawk LH4 is your ultimate tool for precision and creativity.

Transform your projects with the LaserHawk LH4 – where innovation meets craftsmanship. Experience the difference today and elevate your engraving and cutting capabilities to new heights.

More you like:

Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3 | Laser engraver machine✓Laser for engraving machine✓Laser cutter and engraver✓LaserHawk LH4 | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series

Brian Schmidt (verified owner) –

**Industrial Designer’s Experience with Laser Engraver**

As an industrial designer, my experience with the laser engraver has been transformative, particularly in enhancing both project efficiency and design quality. Here are two key aspects of my experience:

### Specific Project Experience: Custom Wedding Decorations

– **Materials Used:** I primarily worked with wood and acrylic for custom wedding decorations, such as menus and name placeholders.

– **Material Behavior:** Wood required careful management to prevent charring, while acrylic needed precise temperature control to avoid melting. This was crucial for maintaining the integrity of intricate designs.

– **Challenges & Solutions:** Ensuring fine details without burning in wood involved adjusting power levels and focal points. For acrylic, using cooling systems helped achieve smooth edges and professional finishes.

### Technical Performance

– **Power & Precision:** The laser engraver’s consistent 10W output allowed for precise engraving, essential for delicate patterns on both materials.

– **Software Experience:** Integration with design software like Fusion 360 facilitated complex designs. Plugins were particularly helpful in mapping intricate floral patterns accurately onto wood and acrylic.

– **Special Features:** Utilizing auto-focusing ensured consistent results across various materials, reducing the need for manual adjustments and enhancing overall efficiency.

### Business Impact

The laser engraver significantly boosted my workflow, enabling quicker production times and higher quality outcomes. This led to positive customer feedback, with clients appreciating the attention to detail and finish quality. The tool’s precision reduced material waste and errors, making it a cost-effective addition to my studio. Overall, it has allowed me to take on more custom projects, enhancing my business capabilities and leading to repeat customers and referrals.

This experience highlights how the laser engraver not only enhances creative possibilities but also improves operational efficiency, making it an invaluable tool in my design process.

Maria Martin –

“Exceptional laser engraver! Precision and detail in every cut, intuitive software, swift operation, and robust build quality. Highly reliable and efficient—a true 5-star experience.”