Exploring the Capabilities of CNC Laser Engravers: A Comprehensive Guide

When it comes to precision and creativity in manufacturing, CNC laser engravers have revolutionized the way we design and produce custom items. These machines are not only versatile but also highly efficient, making them a favorite among professionals and hobbyists alike. Whether you’re working with wood, metal, or other materials, a CNC laser engraver can help you achieve intricate designs and patterns that were once unimaginable. In this article, we will delve into the features, applications, and benefits of these machines, as well as answer some common questions to help you decide if a is right for your needs.

What is a CNC Laser Engraver?

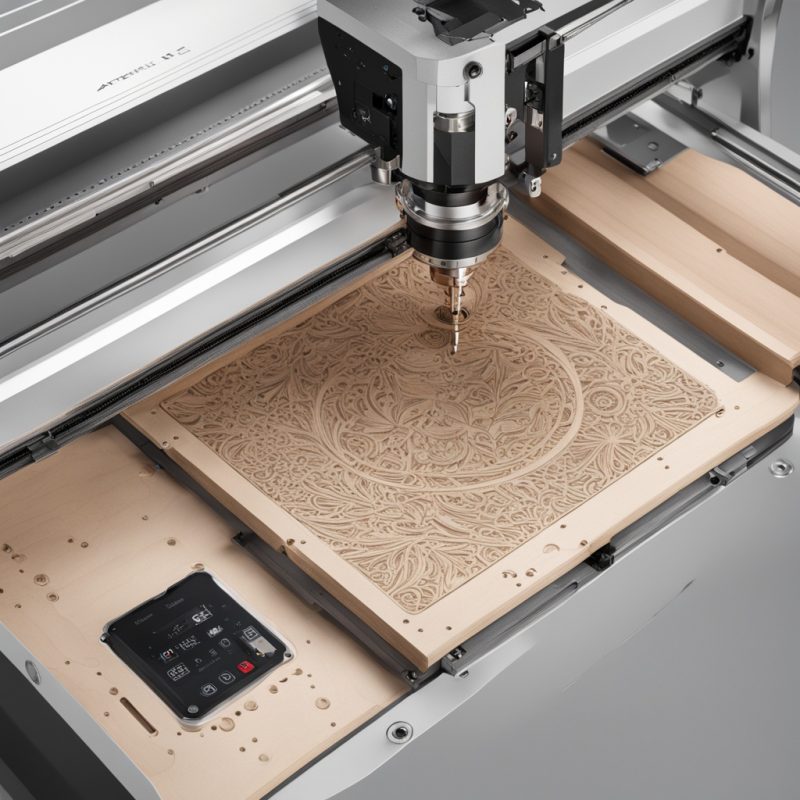

A CNC (Computer Numerical Control) laser engraver is a machine that uses a high-powered laser to cut and engrave materials with precision. Unlike traditional engraving methods, which rely on mechanical tools, laser engravers use light beams to create detailed designs. The process involves feeding digital designs into the machine, which then translates them into physical engravings or cuts. This technology is widely used in industries such as woodworking, metalworking, advertising, and jewelry making.

The key advantage of a CNC laser engraver lies in its ability to handle complex designs with ease. By using software to program the machine, users can create intricate patterns that would be nearly impossible to achieve manually. This level of precision makes it an invaluable tool for both small-scale projects and large production runs.

Key Features of CNC Laser Engravers

CNC laser engravers come equipped with a variety of features that make them indispensable in modern manufacturing. Here are some of the most notable ones:

- Precision Cutting and Engraving: The laser beam can cut or engrave materials with exceptional accuracy, ensuring that even the finest details are captured.

- Versatility in Materials: These machines can work with a wide range of materials, including wood, metal, plastic, glass, and. This makes them suitable for diverse applications.

- Speed and Efficiency: CNC laser engravers are designed to operate at high speeds, reducing production time while maintaining quality.

- User-Friendly Interface: Modern machines often come with intuitive software that allows users to easily upload designs and control the machine’s settings.

- Customization Options: With advanced software, users can create custom patterns, adjust laser power, and fine-tune engraving depth for unique results.

Applications of CNC Laser Engravers

The applications of CNC laser engravers are vast and varied. From small businesses to large-scale manufacturers, these machines are used in numerous industries. Here are some common applications:

- Woodworking: Woodworkers use laser engravers to create intricate designs on furniture, decorative items, and signage.

- Metal Engraving: Metal engravings are widely used in jewelry making, awards, and custom metal signs. The precision of the laser ensures that even delicate details are preserved.

- Glass Etching: Laser engravers can etch intricate designs on glass, creating elegant decorative items or functional products like stained glass windows.

- Advertising and Signage: Businesses rely on laser engravers to create high-quality signs, logos, and promotional materials.

- Jewelry Making: Jewelers use these machines to carve detailed patterns into metal, creating unique pieces that stand out in the market.

Advantages of Using a CNC Laser Engraver

Beyond their versatility and precision, CNC laser engravers offer several advantages over traditional engraving methods. Here are some key benefits:

- High Precision: The laser beam ensures that designs are reproduced with exceptional accuracy, minimizing errors and waste.

- Reduced Material Waste: Unlike mechanical tools, which can leave behind material residue, lasers cut cleanly, reducing waste and saving costs.

- Fast Production Times: CNC laser engravers operate at high speeds, allowing for quick turnaround times on projects. This is especially beneficial for businesses with tight deadlines.

- Ease of Use: Modern machines are designed with user-friendly interfaces, making them accessible even to those without extensive technical expertise.

- Cost-Effective: While the initial investment in a CNC laser engraver can be significant, the long-term savings from reduced material waste and faster production make it a worthwhile investment for many businesses.

Frequently Asked Questions About CNC Laser Engravers

If you’re considering purchasing a CNC laser engraver, you may have several questions. Here are some of the most common ones:

- How much does a CNC laser engraver cost? The cost varies depending on the size, power, and features of the machine. Entry-level models can range from $500 to $2,000, while high-end industrial machines can cost upwards of $10,000 or more.

- What materials can a CNC laser engraver work with? These machines are compatible with a wide variety of materials, including wood, metal, plastic, glass, and. However, it’s important to check the machine’s specifications to ensure compatibility with your chosen material.

- Is it difficult to learn how to use a CNC laser engraver? Modern machines come with intuitive software and user-friendly interfaces, making them relatively easy to learn. There are also numerous tutorials and resources available online to help users get started.

- Can I create custom designs with a CNC laser engraver? Absolutely! With the right software, you can create and upload custom designs to the machine, allowing for endless creative possibilities.

- How much maintenance does a CNC laser engraver require? Like any machinery, CNC laser engravers require regular maintenance to ensure optimal performance. This includes cleaning the lens, checking the alignment, and replacing consumables as needed.

Conclusion

CNC laser engravers are a game-changer in the world of manufacturing and design. Their precision, versatility, and efficiency make them an invaluable tool for professionals and hobbyists alike. Whether you’re creating custom furniture, intricate jewelry, or promotional materials, these machines offer unparalleled capabilities that can take your projects to the next level.

If you’re considering investing in a , it’s important to research and compare different models to find one that best fits your needs. With the right machine, you can unlock new creative possibilities and take your work to new heights.